In modern electrical engineering, transformers play a vital role in transmitting electrical energy over long distances with minimal loss. Among the many types of transformers, step-up transformers are of particular significance in power distribution networks. Their primary function is to increase the voltage from the primary side to the secondary side of the transformer, allowing efficient energy transmission across extensive distances. This article delves into the working principles, construction, and applications of step-up transformers, offering a clear and comprehensive explanation suitable for both professionals and individuals with limited technical knowledge.

What is a Step-Up Transformer?

A step-up transformer is a type of electrical transformer used to increase (or “step up”) the voltage from the primary side (input) to the secondary side (output), while simultaneously decreasing the current. This type of transformer is commonly used in the transmission of electricity across vast distances to reduce power losses. It is called a “step-up” transformer because the voltage is raised (stepped up) from a lower level to a higher level.

Transformers, including step-up transformers, operate on the principle of electromagnetic induction. This principle states that a change in the magnetic field inside a conductor induces a voltage in the conductor. In the case of a transformer, two coils (primary and secondary) are placed near each other, and when current flows through the primary coil, it creates a changing magnetic field that induces a voltage in the secondary coil. The ratio of the number of turns of wire in the primary coil to the secondary coil determines whether the transformer steps up or steps down the voltage.

How Does a Step-Up Transformer Work

At the core of a step-up transformer lies the principle of electromagnetic induction. It is based on the interaction between two coils of wire (primary and secondary) and a magnetic field. Here is an overview of how a step-up transformer works:

Alternating Current (AC) Supply to Primary Coil: When an alternating current (AC) is supplied to the primary coil, it creates a varying magnetic field around the coil.

Magnetic Flux Linkage: The varying magnetic field produced by the current flowing through the primary coil links to the secondary coil, which is placed in close proximity.

Induction of Voltage in Secondary Coil: According to Faraday’s Law of Electromagnetic Induction, a changing magnetic flux passing through the secondary coil induces a voltage in the coil. The magnitude of this induced voltage depends on the number of turns in the secondary coil and the rate of change of the magnetic field.

Voltage Increase: In a step-up transformer, the secondary coil has more turns than the primary coil. As a result, the voltage induced in the secondary coil is higher than the voltage in the primary coil.

Power Transfer: The transformer maintains power (with some minor losses due to resistance and inefficiency), which means that while the voltage increases in the secondary coil, the current decreases proportionally. The power equation P=V×I ensures that the power remains nearly constant between the primary and secondary windings.

Voltage and Current Relationship in Step-Up Transformers

The relationship between the primary and secondary voltages and currents in a step-up transformer is governed by the turns ratio. The turns ratio is defined as the ratio of the number of turns in the primary coil (Np) to the number of turns in the secondary coil (Ns).

The formula for a step-up transformer is:

Vs/Vp=Ns/Np

Where:

- Vp = Voltage in the primary coil

- Vs = Voltage in the secondary coil

- Np = Number of turns in the primary coil

- Ns = Number of turns in the secondary coil

For a step-up transformer, Ns>Np, meaning that the number of turns in the secondary coil is greater than that in the primary coil. This leads to an increase in voltage from primary to secondary.

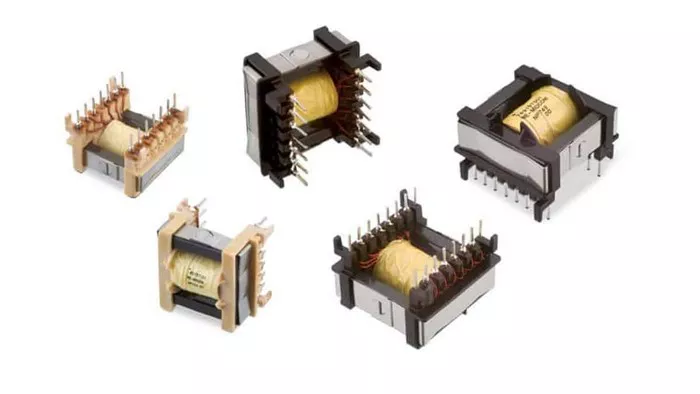

Construction of a Step-Up Transformer

A step-up transformer consists of several key components:

Core: The core of a transformer is typically made from laminated sheets of silicon steel to reduce energy losses due to eddy currents. The core serves as the magnetic path for the flux produced by the current in the coils. The core’s material is selected to have high magnetic permeability to efficiently transfer the magnetic flux between the primary and secondary windings.

Primary Coil: This is the coil through which the input AC voltage is supplied. The primary coil is made from copper or aluminum wire and is wound around the core. The number of turns in the primary coil determines the input voltage and current.

Secondary Coil: This coil is where the voltage is stepped up. The secondary coil is also wound around the core, and its number of turns is greater than that of the primary coil to achieve the voltage increase.

Insulation: Both the primary and secondary windings are insulated from each other and the core. Insulation is necessary to prevent short circuits and to handle the high voltages involved.

Tap Changer: Some step-up transformers are equipped with a tap changer that allows for varying the voltage level on the secondary side. This is useful in situations where the voltage output needs to be adjusted for different transmission distances or requirements.

Efficiency and Losses in Step-Up Transformers

While transformers are highly efficient, they are not 100% perfect. Energy losses occur in a transformer primarily due to the following factors:

Core Losses (Hysteresis and Eddy Currents): As the magnetic flux changes in the core, it causes energy loss due to the resistance of the core material. Hysteresis loss occurs due to the magnetic domain rearrangements in the core material. Eddy current loss occurs due to circulating currents induced in the conductive core material.

Copper Losses: These losses occur due to the resistance of the windings (both primary and secondary). The current flowing through the copper windings causes heating, which results in power loss.

Leakage Flux: Not all the magnetic flux generated by the primary coil links perfectly to the secondary coil. Some flux leaks out and does not contribute to inducing voltage in the secondary coil, leading to inefficiency.

Despite these losses, step-up transformers typically have efficiency levels in the range of 95% to 99%, making them highly effective for their intended purpose.

Applications of Step-Up Transformers

Step-up transformers are critical components in power generation and transmission systems. They are used in various industries and applications, including:

Power Transmission: Step-up transformers are commonly used at power plants to increase the voltage before transmitting electricity over long distances. The high voltage reduces the energy loss due to resistance in transmission lines, as power loss is proportional to the square of the current. By stepping up the voltage, the current is reduced, and energy loss is minimized.

Substation Voltage Transformation: In substations, step-up transformers are used to increase the voltage for long-distance transmission. They ensure that electrical energy can be sent efficiently across the grid.

Renewable Energy Systems: Step-up transformers are used in solar power stations, wind farms, and other renewable energy systems to match the voltage output of renewable sources with the transmission system’s requirements.

Electromagnetic Equipment: High-voltage equipment, such as X-ray machines, require step-up transformers to increase the voltage to the necessary levels for operation.

Industrial Applications: Step-up transformers are used in industries that require high voltage for processes like electroplating, heating, and electric arc welding.

Advantages of Step-Up Transformers

Efficiency in Power Transmission: By stepping up the voltage and reducing the current, step-up transformers help in transmitting power over long distances with reduced losses.

Cost-Effective: Using high-voltage transmission reduces the size and cost of transmission lines, transformers, and other components.

Compact Design: Step-up transformers allow for efficient use of space while providing high voltage, which is essential in applications where space is limited.

Reliable and Safe Operation: With proper design and insulation, step-up transformers offer reliable performance for decades with minimal maintenance.

Conclusion

Step-up transformers are indispensable in modern electrical engineering, especially in the transmission of electricity over long distances. By increasing voltage and reducing current, these transformers facilitate the efficient delivery of power, minimizing energy loss and ensuring that electrical energy reaches consumers in an effective and cost-efficient manner. With advancements in transformer design and materials, step-up transformers continue to be crucial in powering industries, homes, and businesses worldwide. Understanding their working principles, construction, and applications provides insight into the critical role they play in the modern electrical grid.