In the modern world, electricity has become an essential part of everyday life, powering homes, businesses, hospitals, industrial facilities, and more. However, power interruptions, whether due to weather conditions, system faults, or other unforeseen events, can cause significant disruption. Standby generators play a critical role in mitigating the effects of power outages by providing an automatic, reliable backup power source when the main utility fails.

This article explores what a standby generator is, how it functions, its components, and its various applications. It will also discuss why standby generators are crucial for ensuring a continuous power supply and the benefits they offer in various sectors.

What is a Standby Generator?

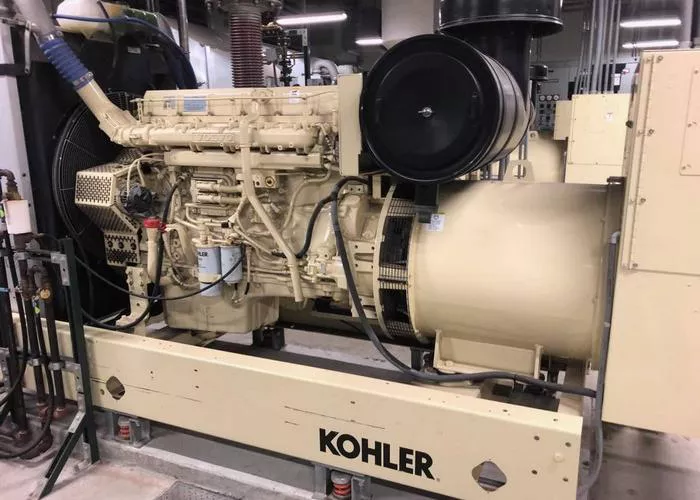

A standby generator is a power backup system designed to automatically provide electrical power to a home, business, or facility in the event of a power failure. Unlike portable generators, which need to be manually started and connected when the power goes out, a standby generator is permanently installed and connected to the electrical system of the building. It runs automatically and provides power within seconds of detecting a power outage, ensuring minimal disruption to the operation of critical systems.

Standby generators are typically powered by either gasoline, natural gas, or diesel, and their capacity ranges from small residential units to large industrial-sized generators. They are commonly used in residential homes, commercial buildings, medical facilities, and data centers, where a reliable and constant power supply is vital.

How Does a Standby Generator Work?

A standby generator works by detecting a loss of power from the utility company and then automatically starting to provide backup power. This process involves several components working together to ensure a smooth transition from the grid power to the generator power. Let’s take a closer look at how these components function and how the system operates.

1. Automatic Transfer Switch (ATS)

The heart of a standby generator is the Automatic Transfer Switch (ATS). The ATS continuously monitors the incoming utility power. When it detects a power outage, it sends a signal to the generator to start. Simultaneously, the ATS disconnects the home or facility from the utility power grid and prepares to connect the generator once it is running.

The ATS ensures a seamless transition between grid power and generator power. It also monitors the generator’s performance, making sure it is running at optimal levels. When the power is restored, the ATS switches back to the utility grid and shuts off the generator, ensuring that the generator is not unnecessarily running once it is no longer needed.

2. Power Source

Standby generators typically run on one of three fuel types: natural gas, diesel, or propane. The choice of fuel depends on various factors, including availability, cost, and environmental considerations.

Natural Gas: Many residential and commercial standby generators are powered by natural gas, which is a clean-burning, readily available, and cost-effective fuel. A major advantage of natural gas is that it is supplied through an existing pipeline, meaning there is no need for refueling during an outage. However, natural gas may not be available in all areas, and supply interruptions can occur.

Diesel: Diesel-powered generators are commonly used for larger backup applications, especially in industrial and commercial settings. Diesel generators are known for their robustness, fuel efficiency, and reliability. However, they require periodic refueling, and the cost of diesel fuel can fluctuate.

Propane: Propane is another popular option, particularly for homes in rural areas where natural gas is unavailable. Propane has a longer shelf life than gasoline and diesel, which makes it suitable for long-term storage.

3. The Generator Engine

At the core of every standby generator is an engine that converts the mechanical energy from fuel combustion into electrical energy. This engine typically operates in a similar manner to the engine in a car, utilizing an internal combustion process to generate the necessary power.

The engine’s output is fed into an alternator, which then converts the mechanical power into alternating current (AC) electrical power. The engine size and design will vary depending on the power needs of the building or facility it is designed to serve.

4. The Alternator

The alternator is the part of the generator that converts mechanical energy into electrical energy. It is made up of a rotor (the rotating part) and a stator (the stationary part), which work together to produce AC power. As the engine turns the rotor, it induces a magnetic field, which in turn generates electricity in the stator windings.

The alternator’s output is typically regulated by a voltage regulator that ensures the generator produces a consistent voltage, making it suitable for powering sensitive electrical equipment without risk of damaging them.

5. Control Panel

The control panel provides an interface between the generator and the user. It allows for easy monitoring of the generator’s status, including fuel levels, power output, and maintenance alerts. Some modern control panels also feature remote monitoring capabilities, enabling users to check the generator’s status via smartphones or computers.

6. Exhaust System

The exhaust system is responsible for safely directing the exhaust gases produced during the combustion process away from the generator and the building. The exhaust system includes a muffler, which reduces the noise produced by the engine, and a flue or pipe that vents the gases outside.

7. Battery System

Standby generators typically rely on a battery system to start the engine. The battery provides the initial power to crank the engine and begin the power generation process. It is essential that the battery is kept charged, and most modern standby generators have an automatic battery charger built into the system to ensure the battery is always ready when needed.

Types of Standby Generators

Standby generators come in different sizes and configurations, each suited for specific needs and applications. The most common types of standby generators are:

1. Residential Standby Generators

Residential standby generators are designed to provide backup power to homes in the event of an outage. They are typically powered by natural gas or propane and range in size from 7kW to 20kW, which is usually sufficient to power essential household appliances such as lights, refrigerators, air conditioning, and heating systems.

These generators are relatively quiet, compact, and easy to install. They are connected directly to the home’s electrical system, and the automatic transfer switch ensures that the generator kicks in immediately when power is lost.

2. Commercial Standby Generators

Commercial standby generators are larger and more powerful than residential units, often ranging from 20kW to 500kW or more. They are used by businesses, factories, offices, and institutions to maintain operations during power outages. Commercial generators can handle a wider variety of loads, including complex electrical systems such as HVAC, elevators, security systems, and more.

These generators are typically powered by diesel or natural gas and are designed for longer running times and heavier loads. They also come with features like remote monitoring and enhanced fuel efficiency.

3. Industrial Standby Generators

Industrial standby generators are heavy-duty units used in large-scale operations such as manufacturing plants, data centers, hospitals, and telecommunications facilities. These generators can provide backup power for an entire industrial complex, with output ratings often exceeding 500kW. They are capable of handling complex electrical loads and are designed for continuous, reliable performance over extended periods.

Industrial standby generators are often built to be more robust, with features such as enhanced cooling systems, advanced fuel management, and built-in redundancy for maximum reliability.

Applications of Standby Generators

Standby generators have a wide range of applications across various industries. Some of the key areas where they are used include:

1. Residential Backup Power

Homeowners use standby generators to maintain power during outages, particularly in areas where storms or other weather-related events are common. These generators ensure that essential appliances, lighting, and heating or cooling systems continue to function, providing comfort and safety.

2. Healthcare Facilities

Hospitals and healthcare facilities rely on standby generators to keep critical medical equipment running during power failures. This includes life-support machines, oxygen generators, and other medical devices that cannot afford to lose power.

3. Data Centers

Data centers require continuous power to maintain server operations, which are essential for businesses that rely on cloud computing and digital services. A power outage can result in data loss, downtime, and severe financial repercussions. Standby generators provide an immediate backup, ensuring that data centers remain operational.

4. Commercial Buildings and Businesses

For commercial establishments such as offices, retail stores, and restaurants, standby generators provide a continuous power supply to keep business operations running. This is particularly important for industries where downtime can cause financial losses, such as in retail or food services.

5. Industrial Applications

Large manufacturing plants, factories, and industrial operations depend on standby generators to ensure production lines continue running, even in the event of a power failure. These generators help avoid costly shutdowns and delays in production schedules.

Benefits of Standby Generators

Uninterrupted Power Supply: The most significant benefit of a standby generator is the assurance that you will have continuous power during an outage. This is critical for businesses, hospitals, and homes that cannot afford to experience downtime.

Convenience: Standby generators automatically start up when a power failure is detected, so there is no need for manual intervention. This makes them highly convenient and reliable.

Cost Savings: While the initial cost of a standby generator can be significant, the potential costs associated with power outages—such as lost productivity, spoiled inventory, or damaged equipment—can be much higher. Standby generators can prevent these losses and provide long-term cost savings.

Enhanced Safety: In areas where power outages can cause hazardous conditions, such as extreme weather, a standby generator ensures that heating, lighting, and other essential systems continue to function, helping keep people safe.

Peace of Mind: Knowing that you have a reliable backup power system in place can provide peace of mind, especially during severe weather events or in critical settings such as healthcare facilities or businesses that rely on uninterrupted power.

Conclusion

Standby generators play a vital role in ensuring a continuous and reliable power supply during electrical outages. Whether in homes, businesses, or industrial settings, these generators provide a crucial safety net, helping to prevent costly disruptions, ensure safety, and maintain business continuity. With automatic startup features, multiple fuel options, and varying power capacities, standby generators have become an essential investment for those who need dependable backup power.