The AC generator, also known as an alternator, plays a crucial role in powering a wide variety of systems and devices in modern society, from household appliances to large-scale industrial machinery. AC generators are integral to electricity generation in power plants, automobiles, and other fields, as they convert mechanical energy into electrical energy, thereby ensuring the supply of alternating current (AC). This article delves into the structure, working principles, types, applications, and advantages of AC generators, while simplifying the concept to make it accessible to readers from various technical backgrounds.

What is an AC Generator?

An Alternating Current (AC) generator is a device that converts mechanical energy into electrical energy in the form of alternating current. It operates on the fundamental principle of electromagnetic induction, discovered by Michael Faraday in the 19th century. In simple terms, when a conductor (usually a coil of wire) moves through a magnetic field, an electric current is induced within the conductor. AC generators are essential for the generation of electricity that powers homes, industries, and large-scale power grids.

How Does an AC Generator Work

The working principle of an AC generator is based on Faraday’s law of electromagnetic induction. Faraday’s law states that the voltage (electromotive force, or EMF) induced in a conductor is proportional to the rate at which the magnetic field through which the conductor moves changes. This principle is leveraged in the construction and operation of AC generators to produce alternating current.

Magnetic Field: A magnetic field is a key component in the functioning of an AC generator. The field is typically produced by magnets, which can either be permanent magnets or electromagnets, depending on the design of the generator. The generator contains a rotating coil (armature) within the magnetic field, and as the coil rotates, the relative motion between the magnetic field and the coil induces an electromotive force (EMF).

Armature: The armature is the part of the generator that contains the coil of wire. The armature rotates within the magnetic field, and as it does, the magnetic flux through the coil changes, generating electricity. The rotational movement of the armature creates a continuous change in the magnetic flux, which results in the alternating nature of the current.

Slip Rings and Brushes: To allow the AC to be extracted from the rotating armature, the AC generator uses slip rings and brushes. Slip rings are conductive rings attached to the rotating shaft, while brushes (typically made of carbon or graphite) are stationary and maintain electrical contact with the slip rings. As the armature rotates, the brushes collect the alternating current generated in the coil and transfer it to the external circuit.

Output Voltage and Frequency: The output voltage and frequency of the generated AC depend on several factors, such as the speed of rotation of the armature, the number of coil turns, and the strength of the magnetic field. The voltage is typically sinusoidal in nature, which is a key characteristic of alternating current. The frequency of the AC is measured in Hertz (Hz) and represents the number of cycles per second. In many countries, the standard frequency for electricity generation is either 50 Hz or 60 Hz.

Types of AC Generators

AC generators can be categorized into different types based on their design, application, and method of excitation. The two main types of AC generators are:

1. Synchronous Generators:

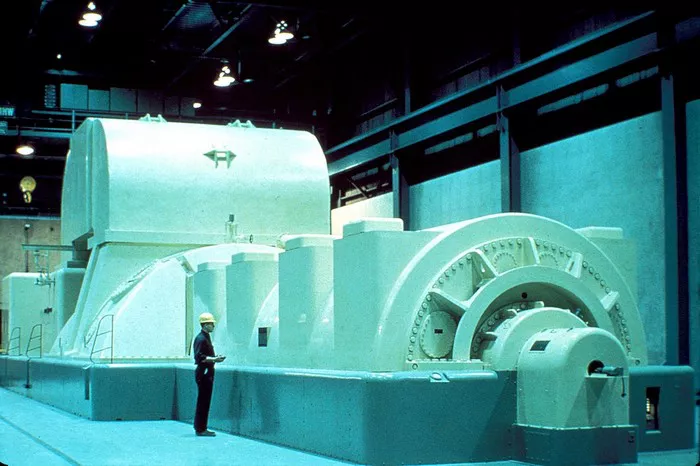

Synchronous generators, also known as alternators, are widely used in power plants for generating electricity in large quantities. In this type of generator, the armature (rotor) rotates at the same speed as the magnetic field produced by the stator, thus synchronizing the rotor’s rotation with the frequency of the AC current. This synchronization ensures that the output current maintains a constant frequency.

Key Features:

- Operates at constant speed.

- Used for high-power generation.

- Provides stable frequency and voltage output.

- Commonly used in power stations, ships, and large industrial setups.

2. Induction Generators:

Induction generators, also known as asynchronous generators, operate on the principle of electromagnetic induction, similar to motors. Unlike synchronous generators, the rotor of an induction generator does not rotate at the same speed as the magnetic field. Instead, it rotates at a slightly slower speed, causing the induction of current in the rotor. Induction generators are often used in small-scale applications such as wind turbines and small hydroelectric plants.

Key Features:

- Operates at variable speeds.

- Relies on external power sources for excitation.

- Often used in renewable energy applications like wind power generation.

Components of an AC Generator

The basic components of an AC generator include:

Rotor: The rotating part of the generator that contains the armature, which is typically wound with a coil of wire. The rotor is driven by mechanical energy, which causes it to rotate within the magnetic field.

Stator: The stationary part of the generator that houses the magnetic field. The stator contains field windings or permanent magnets that produce a magnetic field in which the rotor rotates.

Slip Rings: These are conductive rings attached to the rotor. They allow the electrical current generated in the rotor to be transferred to the external circuit without interruption.

Brushes: Stationary carbon or graphite brushes maintain electrical contact with the slip rings, allowing the transfer of alternating current.

Field Windings (in some designs): Some generators use electromagnets to produce the magnetic field, while others rely on permanent magnets. Field windings are used to provide the necessary magnetic field in generators that require excitation.

Commutator (in DC generators): In some cases, the AC generator is designed to produce direct current (DC) by incorporating a commutator. The commutator is a split ring mechanism that converts the alternating current produced in the armature into direct current, which is useful in some applications.

External Circuit: The external circuit is connected to the slip rings and is where the electrical energy is delivered for use. The output voltage and current can be adjusted using external equipment like transformers and voltage regulators.

Working of an AC Generator

The operation of an AC generator is summarized in the following steps:

Mechanical Input: Mechanical energy, usually in the form of rotational motion, is provided to the generator’s rotor through an external source, such as a steam turbine, internal combustion engine, or wind turbine.

Magnetic Field Interaction: As the rotor turns, the armature (a coil of wire) moves through the magnetic field produced by the stator. The relative motion between the coil and the magnetic field induces an electromotive force (EMF) in the coil.

Induced Current: The EMF causes the electrons in the coil to move, generating an alternating current in the wire. The direction of the induced current changes as the rotor continues to rotate, resulting in the alternating nature of the current.

Power Extraction: The alternating current is collected by the slip rings and brushes, which transfer the electrical energy to the external circuit.

Output Control: The output voltage and frequency are controlled by adjusting the speed of the rotor and the strength of the magnetic field. In synchronous generators, the rotor speed is synchronized with the AC frequency.

Applications of AC Generators

AC generators are used in a wide range of applications, some of which include:

Power Generation Plants: AC generators are the primary source of electricity in power plants, both large and small. In these plants, mechanical energy (from turbines, steam, or water) is converted into electrical energy using AC generators.

Automobiles: In vehicles, alternators are used to charge the battery and power electrical systems. The engine’s mechanical energy is used to drive the alternator, generating AC power that is later converted into DC for use by the vehicle.

Renewable Energy: Wind turbines and hydroelectric generators use AC generators to convert mechanical energy from wind or flowing water into electrical energy. These systems often rely on induction generators or synchronous generators, depending on the application.

Industrial and Household Use: Smaller AC generators, often referred to as portable generators, are used in construction sites, events, and homes to provide backup electricity during power outages.

Aircraft and Ships: AC generators are used in aircraft and marine systems to generate power for lighting, instrumentation, and other electrical needs.

Advantages of AC Generators

AC generators offer several advantages that make them a popular choice for electricity generation:

Efficiency in Long-Distance Transmission: AC can be easily transformed to high voltages, which minimizes energy loss during transmission. High-voltage AC transmission reduces the amount of current required and allows power to be transmitted over long distances without significant energy loss.

Ease of Generation: AC generators are relatively easy to design and build, making them versatile and adaptable to different scales of power generation.

Lower Maintenance Costs: AC generators tend to have fewer moving parts compared to DC generators, leading to lower maintenance costs and longer service life.

Constant Power Output: Synchronous AC generators provide a steady, consistent frequency and voltage output, which is essential for powering sensitive electronic devices and large-scale industrial processes.

Compatibility with Electrical Grid: AC is the standard form of electricity used by most power grids, which makes AC generators directly compatible with the grid for efficient power distribution.

Conclusion

In conclusion, the AC generator is an essential device in modern electricity generation, converting mechanical energy into alternating current through the process of electromagnetic induction. Its simplicity, versatility, and efficiency have made it indispensable in a wide range of applications, from power plants to automobiles and renewable energy systems. Understanding the working principles, components, and advantages of AC generators allows engineers, technicians, and the general public to appreciate the critical role they play in powering the world’s infrastructure. Whether it’s for large-scale power generation or small portable applications, AC generators continue to drive technological advancements in the energy sector.