A barometer is a crucial instrument used to measure atmospheric pressure. These devices are essential for predicting weather changes, determining altitude, and conducting various scientific experiments. While barometers are designed to be precise and durable, there are times when they may not function properly. Understanding the common issues and their causes can help users troubleshoot problems effectively. In this article, we’ll explore why your barometer might not be working, common causes, and how to resolve these issues.

What is a Barometer?

A barometer is a device that measures the atmospheric pressure in a specific location. There are two main types of barometers: mercury barometers and aneroid barometers.

- Mercury Barometer: This is the classic type, featuring a column of mercury contained in a glass tube. The height of the mercury column changes with fluctuations in atmospheric pressure.

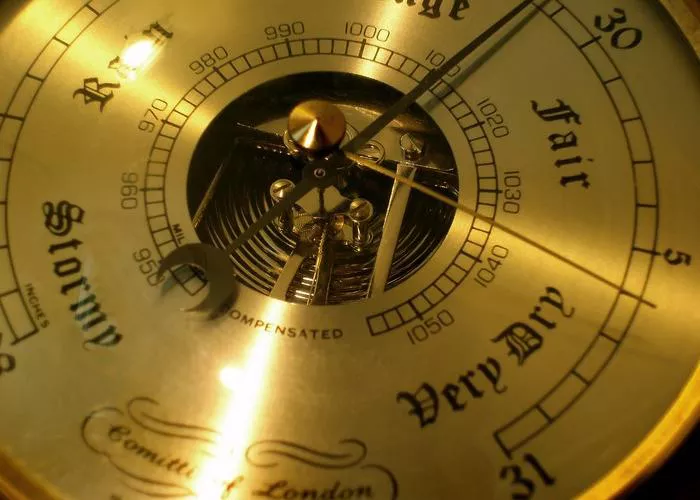

- Aneroid Barometer: This type does not use any liquid. Instead, it uses a flexible metal chamber that expands and contracts with changes in air pressure. These changes are transferred to a pointer that indicates pressure levels on a dial.

Barometers are used in a variety of fields such as meteorology, aviation, and even by hikers and mountaineers to determine altitude. When a barometer is not working, it can cause problems for anyone relying on accurate pressure readings for such applications.

Common Reasons Why a Barometer Might Not Be Working

1. Incorrect Calibration

Calibration is the process of setting a barometer to the correct standard atmospheric pressure. A poorly calibrated barometer will provide inaccurate readings. Over time, the calibration can shift due to mechanical wear, environmental changes, or accidental bumps.

- Mercury Barometers: Mercury barometers should be calibrated based on the known atmospheric pressure at a given location, typically measured at sea level. If the mercury column is too high or too low, the reading will be incorrect.

- Aneroid Barometers: Aneroid barometers are typically adjusted using a screw mechanism at the back of the device. If not calibrated correctly, the reading will be off.

Solution: To recalibrate, you can adjust the barometer using a known reference. For example, if you have access to a nearby weather station or a reliable barometer, you can compare the readings and adjust your device accordingly. For more precise calibration, it’s best to consult the manufacturer’s manual.

2. Environmental Factors

The environment plays a significant role in a barometer’s accuracy and functionality. Extreme weather conditions, temperature fluctuations, and humidity levels can all affect a barometer’s performance.

- Temperature: Temperature changes affect the volume and density of air. A barometer that is not properly shielded from direct heat or cold may give inaccurate readings. For example, mercury expands when it’s heated and contracts when it’s cold. In an aneroid barometer, temperature extremes can cause the metal diaphragm to expand or contract, leading to incorrect readings.

- Humidity: Excessive moisture in the air can cause internal components of the barometer to corrode or degrade over time. In an aneroid barometer, the flexible metal diaphragm could become rusted, affecting its ability to respond to changes in atmospheric pressure.

Solution: Ensure your barometer is located in a stable environment, away from direct heat sources, drafts, or places with fluctuating temperatures. For example, keep it indoors in a climate-controlled room to avoid fluctuations. Additionally, avoid placing the barometer in areas with high humidity like bathrooms or basements.

3. Mechanical Damage

Barometers are sensitive instruments, and mechanical damage can disrupt their functionality. This is especially true for mercury barometers, where physical trauma could cause the mercury to leak or the glass tube to break. Aneroid barometers, which rely on a metal diaphragm, can also suffer damage from knocks, impacts, or excessive pressure.

- Mercury Barometer: If the mercury column inside the tube is disturbed, it may cause the mercury to separate, creating air bubbles. This can prevent the mercury from rising or falling correctly, which leads to inaccurate readings.

- Aneroid Barometer: A damaged metal diaphragm may become bent or misshapen, preventing it from responding accurately to changes in pressure.

Solution: Examine your barometer for visible damage. If there’s a broken tube or visible cracks in a mercury barometer, or if the pointer on an aneroid barometer seems misaligned or stuck, the instrument may need repair or replacement. Handle the barometer gently and avoid subjecting it to any physical shocks.

4. Low or High Altitude Locations

Barometers are calibrated to measure pressure at sea level, but they can also be used to determine altitude by measuring the change in pressure with elevation. If you’re using your barometer at a significantly higher or lower altitude than where it was calibrated, you might experience discrepancies in readings.

- Mercury Barometers: The height of the mercury column decreases as you ascend to higher altitudes because the atmospheric pressure is lower.

- Aneroid Barometers: These devices have a spring-loaded metal capsule that responds to pressure. However, the pressure at higher altitudes will be lower, which may cause inaccuracies if the device was not specifically designed for such use.

Solution: If you’re using a barometer in high-altitude regions, be sure to check its specifications. Some barometers can be recalibrated for altitude changes, while others may require a specific model designed for use at higher elevations.

5. Leaks or Internal Failures in Aneroid Barometers

Aneroid barometers are designed with a sealed metal chamber that responds to changes in atmospheric pressure. Over time, small leaks can develop in the chamber due to corrosion, wear, or defects in the materials. A leak reduces the chamber’s sensitivity to pressure changes, resulting in an unresponsive or inaccurate barometer.

Solution: If your aneroid barometer is no longer responding to changes in pressure, it may be due to an internal leak or malfunction. Unfortunately, repairing this kind of issue usually requires professional help or replacement of the device.

6. Expired or Faulty Components

Many barometers contain moving parts that can wear out over time. In an aneroid barometer, the metal diaphragm and springs are subject to fatigue and corrosion. Similarly, the scale or dial may fade or become misaligned.

Solution: Regular maintenance and inspection can help keep the barometer in working condition. If the instrument has parts that are worn out or defective, replacing the faulty components may restore its functionality.

7. Barometer Type Mismatch for Application

Different barometers are designed for different purposes. If you’re using a device that isn’t suited for your application, it may not perform correctly. For example, using a standard barometer at extreme elevations or in high-precision applications could lead to errors.

Solution: Ensure that the barometer you are using is appropriate for the task at hand. For example, specialized barometers designed for altimeters, aviation, or scientific experiments are available. If you’re unsure about the compatibility, refer to the manufacturer’s guidelines.

How to Fix Your Barometer

If your barometer is malfunctioning, there are several steps you can take to troubleshoot and resolve the issue:

- Check for Visible Damage: Inspect the instrument for cracks, dents, or broken parts.

- Recalibrate the Barometer: Use a known pressure source to recalibrate the barometer. Many barometers also come with a calibration screw for this purpose.

- Relocate the Barometer: Ensure the barometer is placed in a stable environment with minimal temperature fluctuations and away from humidity sources.

- Test Against Another Barometer: If possible, compare the readings of your barometer with another functioning one to identify discrepancies.

- Consult a Professional: If none of the above solutions work, it may be necessary to consult a professional or replace the device.

Conclusion

Barometers are essential tools for measuring atmospheric pressure, but like any mechanical device, they can encounter problems that impair their function. Common issues such as incorrect calibration, environmental factors, mechanical damage, and wear can all lead to inaccurate readings. Regular maintenance, careful handling, and proper calibration can help keep your barometer in optimal working condition. By understanding the common causes of malfunction, you’ll be better equipped to troubleshoot problems and restore accurate pressure measurements.