When it comes to wiring for outdoor applications, selecting the right type of wire for conduit is crucial for ensuring safety, durability, and compliance with electrical codes. Outdoor environments present unique challenges, including exposure to the elements, temperature fluctuations, UV radiation, moisture, and physical wear. This article explores the essential considerations and types of wires suitable for outdoor conduit, ensuring that installations are both functional and reliable for years to come.

1. The Importance of Selecting the Right Wire for Outdoor Conduit

Electrical systems are essential for powering homes, businesses, and industries. When these systems are exposed to outdoor conditions, the wiring must be robust and resilient enough to handle various environmental stresses. Conduits are protective tubes that house electrical wires, shielding them from external damage and minimizing the risk of short circuits or fire hazards.

Outdoor conduit systems, however, require careful attention to the type of wire used. Unlike indoor wiring, outdoor installations are subjected to moisture, UV light, temperature extremes, and physical impact. Therefore, it is essential to choose a wire that is both durable and compliant with electrical codes like the National Electrical Code (NEC).

This article discusses the various wire types suitable for outdoor conduit systems, providing guidance on which wire is best for specific conditions, how to select the appropriate wire, and how to ensure your installation meets safety standards.

2. Key Considerations for Choosing Outdoor Wiring

Before delving into specific wire types, it is important to consider the following factors when selecting wire for outdoor conduit:

Environmental Conditions

Outdoor environments are highly variable, with factors such as:

- Moisture and Water Exposure: Outdoor installations often face exposure to rain, snow, or high humidity. Wires used in outdoor conduits must be moisture-resistant to prevent short-circuiting and corrosion.

- Temperature Variations: Outdoor wires should be able to withstand a broad range of temperatures. Extreme cold or heat can affect the insulation material and overall wire performance.

- UV Radiation: Ultraviolet (UV) radiation from the sun can degrade some materials over time, causing them to become brittle or break down. This is especially true for wires with unprotected or poorly insulated jackets.

- Physical Damage: Outdoor conduits are more susceptible to physical damage from animals, tree branches, lawn mowers, and other hazards.

Code Compliance

The National Electrical Code (NEC) outlines stringent standards for wiring in different environments, including outdoor installations. Compliance with the NEC is not just a matter of legality, but also of safety. Make sure the wire and conduit you choose are rated for outdoor use and approved by regulatory bodies.

Durability and Longevity

Outdoor wires must have a long service life and be resistant to wear and tear. Durability depends on factors such as material composition, insulation type, and environmental resistance.

3. Types of Wires for Outdoor Conduit

Different types of wires are available for use in outdoor conduit, each with its specific advantages and applications. Let’s examine some of the most commonly used wire types:

THWN-2 Wire

One of the most popular types of wire for outdoor conduit is THWN-2 (Thermoplastic Heat and Water-Resistant Nylon-Coated) wire. It is designed specifically to withstand wet conditions and extreme temperatures. The “2” designation means it is rated for 90°C (194°F) in dry locations and 75°C (167°F) in wet locations. These wires are suitable for use in outdoor environments that may experience exposure to water, such as underground installations or systems subjected to rain.

Key Features:

- Moisture-resistant and capable of withstanding water exposure.

- UV-resistant, making it suitable for direct sunlight exposure.

- Flexible and able to endure temperature extremes.

- Commonly used for residential, commercial, and industrial wiring.

Applications:

- Outdoor lighting systems

- Submersible pumps

- Outdoor electrical panels

- Electrical systems in wet or damp locations

XHHW-2 Wire

Another commonly used wire for outdoor conduit systems is XHHW-2 (Cross-Linked High Heat-Resistant Water-Resistant) wire. XHHW-2 is designed to be both heat and moisture-resistant, making it suitable for high-temperature environments as well as areas prone to water exposure. The cross-linked insulation provides improved durability and resistance to both mechanical and environmental stresses.

Key Features:

- Rated for use in both dry and wet locations (90°C/194°F in both).

- Resistant to oil, water, and chemicals, making it highly durable.

- Offers excellent resistance to UV rays.

- Commonly used in high-temperature and high-moisture environments.

Applications:

- Industrial machinery

- Commercial buildings

- Outdoor electrical systems in damp or wet conditions

UF-B (Underground Feeder) Cable

For applications that require wiring buried directly in the ground, UF-B (Underground Feeder) cable is a popular choice. UF-B cables are designed for direct burial without needing conduit. They are equipped with a heavy-duty insulation that is moisture-resistant and can handle both outdoor exposure and direct earth contact.

Key Features:

- Suitable for direct burial, with a tough outer jacket that resists moisture, abrasion, and sunlight.

- No need for conduit when buried underground.

- Comes with copper or aluminum conductors and is often used in residential and commercial settings.

Applications:

- Running power to outdoor structures like sheds, garages, or pools.

- Residential outdoor lighting.

- Agricultural applications where cables need to be run underground.

SER (Service Entrance) Cable

For outdoor power distribution, SER (Service Entrance) cable is often used. It is a multi-conductor cable that is designed to be used for the main power feed to a building. SER cables are insulated to handle both moisture and temperature extremes and are commonly used in service entrance systems for homes and businesses.

Key Features:

- Typically used for incoming power lines.

- Often has a strong jacket designed to resist damage from moisture, abrasion, and sunlight.

- Available in copper or aluminum conductors.

Applications:

- Service entrance wiring.

- Main power supply for residential and commercial buildings.

THHN Wire

THHN (Thermoplastic High Heat-resistant Nylon-coated) wire is a standard wire commonly used in both indoor and outdoor conduit. While it is primarily designed for dry conditions, THHN wires can also be used outdoors when placed in conduit that provides added protection against environmental factors.

Key Features:

- Heat-resistant (up to 90°C/194°F in dry conditions).

- Strong insulation provides resistance to oil, heat, and mild abrasions.

- Works best when protected from direct moisture or sunlight exposure, such as within a conduit system.

Applications:

- General-purpose wiring for electrical circuits in buildings.

- Indoor and outdoor conduit systems when used with additional protective measures.

4. Choosing the Right Wire for Specific Applications

While various wire types are suitable for outdoor conduits, the decision depends on several factors, including environmental conditions, project requirements, and local electrical codes. Below are some recommendations based on common outdoor applications:

For Wet Locations (Pools, Fountains, etc.)

- Recommended Wire: THWN-2 or XHHW-2.

- Reason: Both of these wire types offer moisture resistance and are rated for use in wet conditions. XHHW-2 is especially suitable for high-heat environments and industrial applications.

For Underground Applications (Direct Burial)

- Recommended Wire: UF-B Cable.

- Reason: UF-B is specifically designed for underground use without conduit, providing moisture resistance, durability, and a strong outer jacket for physical protection.

For Residential Outdoor Lighting

- Recommended Wire: THWN-2.

- Reason: THWN-2 offers moisture and UV resistance, making it ideal for outdoor lighting circuits exposed to the elements.

For Power Distribution and Service Entrances

- Recommended Wire: SER Cable.

- Reason: SER is ideal for main power feeds and service entrances, offering high durability and resistance to physical damage, moisture, and sunlight.

5. Installation Considerations

Once you have selected the right wire, it is important to ensure that the conduit installation is properly executed:

Conduit Type: Choose the appropriate conduit type based on environmental conditions. For outdoor applications, use conduits like PVC, Rigid Metal Conduit (RMC), or Intermediate Metal Conduit (IMC), which offer both physical protection and moisture resistance.

Wire Sizing: Properly size the wire to ensure safe and efficient operation. Check electrical codes and load requirements to avoid overheating or electrical hazards.

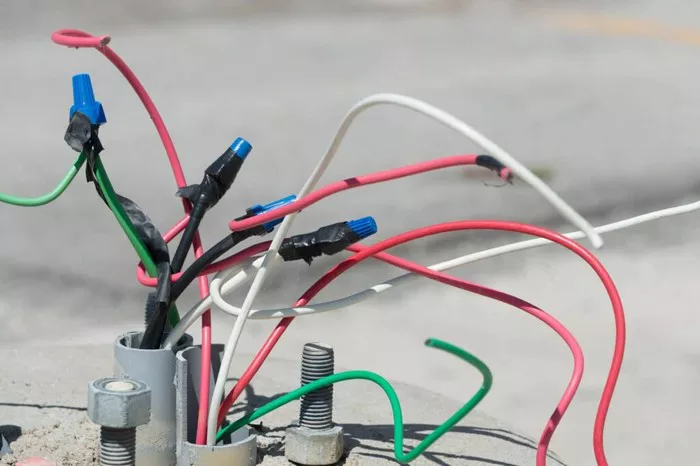

Sealing and Protection: When routing wires through outdoor conduits, ensure that the ends are properly sealed to prevent moisture from entering. Use junction boxes or weatherproof enclosures for connections.

Conclusion

Selecting the right wire for outdoor conduit is essential for ensuring long-lasting, safe, and efficient electrical installations. Consider environmental factors such as moisture, temperature, UV radiation, and physical wear when choosing wire types. Wires such as THWN-2, XHHW-2, UF-B, and SER offer excellent durability for outdoor applications, each designed to withstand specific conditions.

By following the guidelines discussed in this article and ensuring that the installation meets local electrical codes, you can ensure that your outdoor electrical systems are both safe and reliable, minimizing risks and maximizing their lifespan. Proper wire selection and installation are key to avoiding future electrical issues and ensuring a safe and efficient outdoor electrical system.