Arburg Ltda., a leading player in the Brazilian plastics industry, is set to make a major impact at Plástico Brasil 2025, South America’s key plastics trade fair. The company, which has deep roots in Brazil, will showcase a cutting-edge turnkey system designed specifically for the packaging sector, demonstrating the efficiency of its injection moulding solutions.

Alfredo Fuentes, Managing Director of Arburg Ltda., emphasized the significance of the event: “Plástico Brasil is a vital platform for both our country and the entire South American market. We aim to highlight our innovative injection moulding system, tailored for the packaging industry—a sector with vast growth potential in Brazil.”

Arburg’s goal at the event is to position its injection moulding solution as an efficient alternative to traditional thermoforming. Fuentes explained, “The production of IML (In-Mould Labelling) cups is a prime example of how optimised process control can achieve faster cycle times while maintaining high productivity and process stability.”

Hybrid High-Performance Allrounder on Display

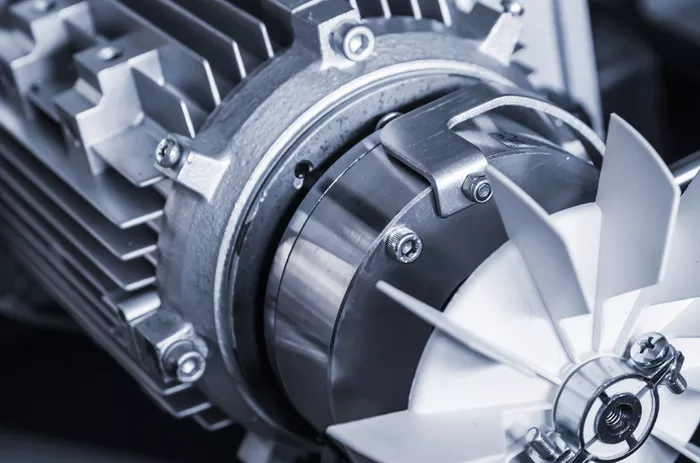

Arburg will feature its hybrid Allrounder 720 H in packaging configuration, a machine specially designed for IML applications that require high-speed, high-quality production with minimal material and energy consumption. The Allrounder combines an energy-efficient, precise electric clamping unit with a dynamic, powerful hydraulic injection unit.

On display at Plástico Brasil 2025, the Allrounder 720 H will demonstrate its capabilities by producing four 250-millilitre IML margarine containers in a cycle time of under five seconds. The IML automation, provided by Brazilian manufacturer G3 Automation, will be coupled with a 4-cavity mould from RK Ferramentaria, creating an efficient, high-output solution. The machine is controlled via the Gestica system, which incorporates advanced “smart” functions for improved operational convenience and support.

Optimised for Packaging

The packaging version of the Allrounder machine, specifically developed by Arburg for the packaging sector, is equipped with FEM-optimised mould mounting plates and robust machine bases. It also features wear-resistant cylinder modules, barrier screws, and servo-electric toggle-type clamping units. These components are designed to deliver short dry cycle times, high plasticising capacity, fast injection speeds, and reduced energy consumption, ensuring a highly efficient production process.

Leveraging Digitalisation for Efficiency

In addition to showcasing its high-performance machines, Arburg will highlight its digitalisation solutions at Plástico Brasil 2025. The company’s digital products and services offer customers the ability to enhance production efficiency and transparency in their injection moulding operations. Arburg’s exhibit will be networked with the Arburg ALS host computer system, enabling real-time visualisation of key process data and performance metrics.

Attendees will also be introduced to Arburg’s customer portal, arburgXworld, which offers access to preventive maintenance, real-time production insights, and a wide range of after-sales services designed to optimise the lifecycle of Arburg machines.

As part of its comprehensive approach, Arburg will demonstrate that it provides “more than just a machine” by offering complete solutions that drive long-term efficiency improvements and sustainability for manufacturers in the packaging sector.